Technology

Using extensive networks, technology and innovative solutions are pursued, not as widgets, but as sustainable, integrated solutions

Novel Equipment and Systems

The improvement of mining and processing systems through the application of appropriate technology and innovation has been a longstanding aim for both BRS and Dr. Ted Bearman. The commitment to technological advancement is demonstrated by the publication record of BRS and involvement in various technology assessment projects.

Since 2019, Ted Bearman has been an Honorary Professor in Mineral Processing, in the Chemical Engineering Department of the University of Nottingham. This collaboration is predominantly aimed at the deployment and demonstration of comminution and liberation enhancement through the application of microwave energy.

Other technology areas targeted by BRS have included preconcentration, novel and/or improved comminution methods, flowsheet development, soft sensors, improved characterization of material and automation.

Technology Scouting and Future Direction

BRS actively maintains a forward looking perspective to ensure that it stays aware of developments and leading-edge work, in and around, mining and processing.

Involvement in technology projects and active participation in generating technical papers and conference attendance, are all part of the networking that provides BRS with a current and in-depth view of future opportunities.

We work across industry end users, equipment suppliers and academia to both understand and influence technology development.

Through these initiatives BRS can offer Clients up to date views of the global R&D and innovation landscape and how developments in these areas may provide value adding opportunities.

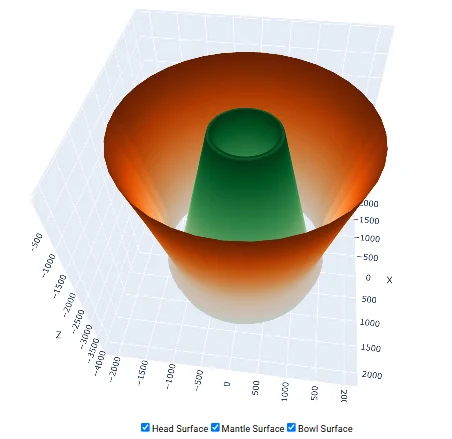

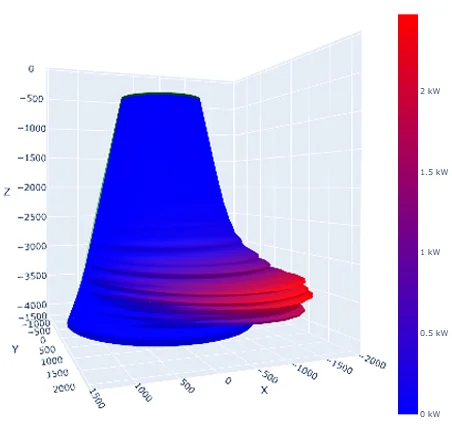

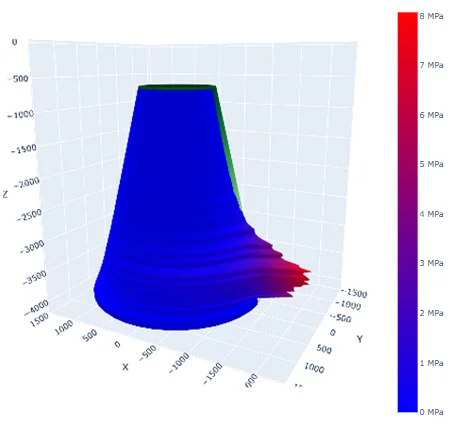

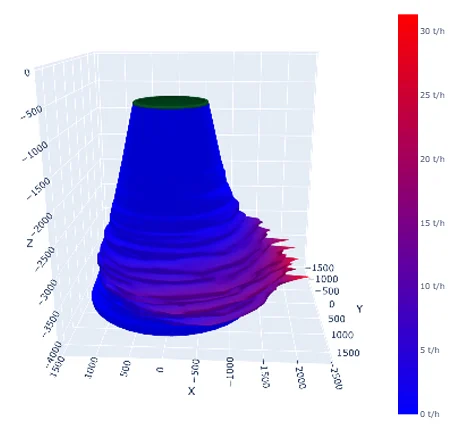

Kinematic Crusher Model (KCM)

In process modelling and simulation, BRS have worked extensively with Met Dynamics (Scott Munro).

Jointly, BRS and MD offer the Kinematic Crusher Model (KCM), both as a consulting tool, but also options exist for Clients to access the model via specific arrangements.

KCM allows in-depth analysis of crusher performance based on the geometry of the machine, feed properties and operational factors. Such analysis is unique in its ability to identify potential operational and mechanical issues and provide solid estimates of process performance.

KCM holds a model database that covers a wide range of cone crushers including Metso Symons/GP/HP/MP, FLS XL Raptor, Sandvik CH, Kawasaki and Terex and primary crushers from all major manufacturers. Using detailed crusher geometry (including liner profiles), predictions of throughput, product size distribution, power consumption and crushing force over wear life can be provided to clients. Analysis also includes the impact of choke level and interaction with screens and the resulting closed circuit performance.

KCM can be used either as a stand-alone model or incorporated into a full flowsheet simulation along with other comminution and downstream processing equipment.

Beyond KCM, BRS-MD offer advanced flowsheet modelling using the SysCAD platform. Under this arrangement, the full suite of proprietary process models are available to be used in BRS projects.